Jay Fisher - Fine Custom Knives

New to the website? Start Here

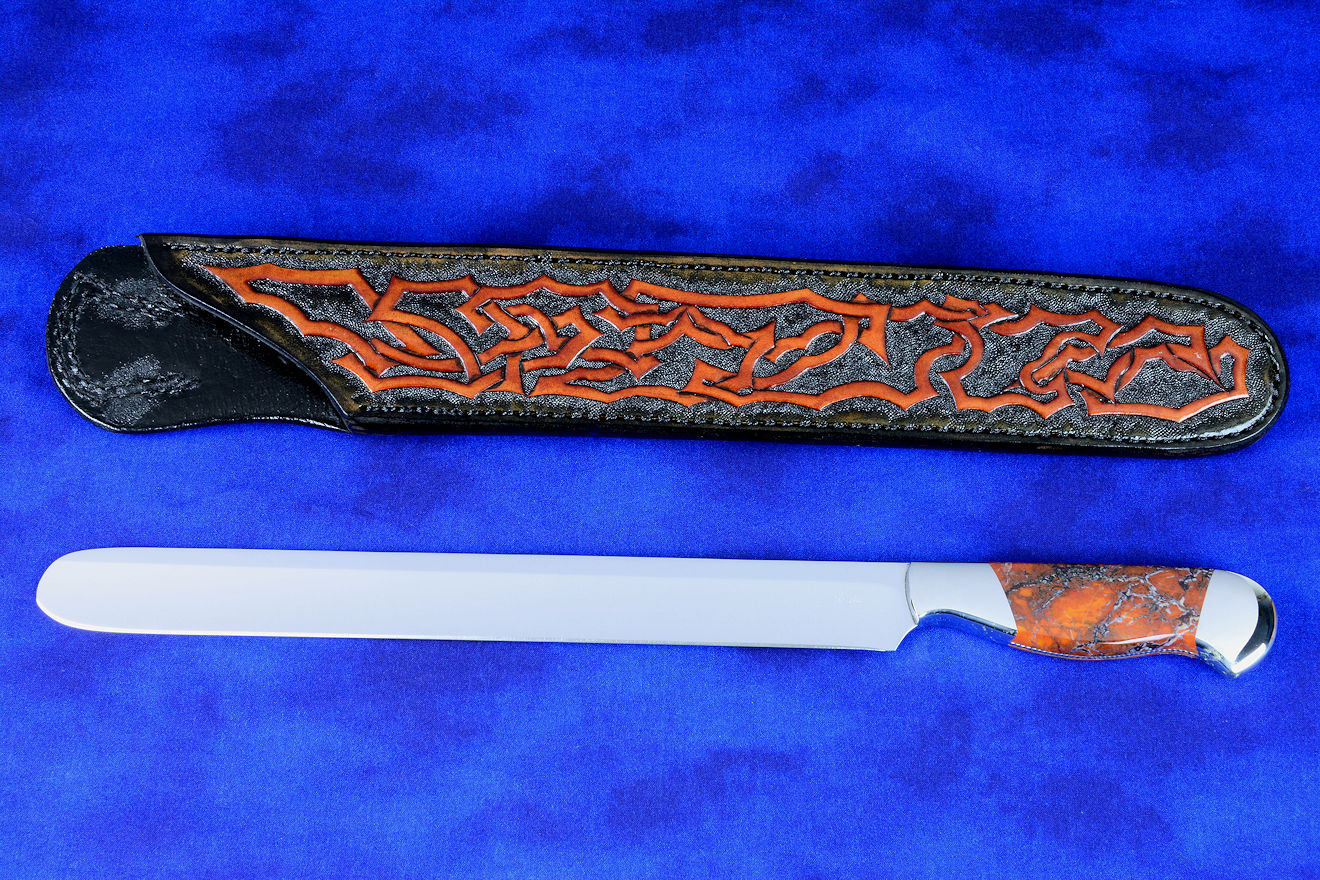

"Cassiopeia"

Jay,

First, MERRY CHRISTMAS!

K. absolutely loves the knives and sculpture! She marveled at the balance and said each knife felt like a part

of her hand and wished she had them for use preparing Christmas dinner last night. She recognized it immediately

as an incredible work of art.

We both thank you from the bottom of our hearts for your “Labor of Love” – it shows in every detail.

Jay, you know I am a knife collector and have large collections of Loveless and Moran knives among many others.

I have told many of the people in the knife world I deal with that you are the finest working knife maker in America.

So many today are “Copycats” trying in vain to make a Drop Point Hunter or Damascus Fighter, rather than create from

within themselves as you do. Keep it up and continue to be true to yourself.

With our warmest wishes,

K. and L. B. and Family

While others may offer you baseless generalities, notions of great traditional histories, vague and non-specific ideals about their knives alongside tiny photos and very little useful information or specs, I will offer facts, specific descriptions, very clear and abundant evaluations and comparisons for your consideration.

My professional goal is to make the very best chef's knives available in our modern times.

This page is about the knives I make here at Sharp Instinct Studio for culinary use, specifically chef's knives and cutlery, kitchen knives, cook's knives, professional food service knives, meal prep knives, tools, and accessories comprising of but not limited to cutting tools, knives, choppers, cleavers, used to and for slicking, slicing, chunking, julienne, butterfly, chopping spices, cubing, dicing, scoring, shredding, brunoise, preparing stir-fry, slicing bread, fining, grinding, carving, and separating foods, ingredients, and components. I've included some topics that I think you will find worthwhile, and also included thumbnail photographs in captioned boxes with the name of the individual knives. If there is a featured page about the knife, the name is linked to that page. As with all my pages, I'll continually add new projects and knives as they are completed.

As you read this page, you'll probably begin to realize that a lot of what you think, have heard, or read about common chef's and kitchen knives is the result of mass marketing created to sell volume knives. Volume knife sales is a great idea for the masses; knives can be made cheaply and uniformly, in great quantities, by bulk manufacturing interests (mostly in China). The knives made this way are utilitarian, common, and inexpensive. There is nothing wrong with making and marketing knives this way; you get what you pay for, and it's not much, either way.

These are not my clients. My patrons and customers are interested in the very, very best. They want knives that are built with intelligent, modern materials, methods and techniques. They want the absolute premium modern tool steels, they want modern, scientific, accurate and verified heat treatment and cryogenic processing, they want first-class, contemporary fittings and design, they want the pinnacle of art and functional form for the knife that rests in their most honored place of gathering, nourishment, and sharing: their kitchens.

My personal and professional drive is to make and offer these knives through my own creative works as well as through custom works individually suited to each client. The knives you see on this page (and on all the other pages of the site apart from my "Knives for Sale" pages) are sitting in someone's favorite spot in their kitchen, on their counter, on their dining table, or in their restaurant, at the ready, in a place of respect that is important to them. I consider this the greatest honor I can have: that someone has a fine work of art and precision made completely by my hands in their life, that they adopt it to become part of their family of possessions, that the knife or knives are to be handed down to generations to come. This is why I do what I do.

The difference between the work of a professional custom knifemaker and mass-marketed knives is fairly simple to determine, and it can be summed up in the phrase "Quality vs. Quantity." Because there is so much mass marketing hyperbole on the internet, on media sources, in print, on television, and in advertising generally, I've taken considerable time to illustrate what these differences are generally on my "Factory Knives vs. Fine Handmade Knives" page on this website.

There is much more to these comparisons, mainly how my work, inspiration, art, and professional creations differ from other knifemakers who make kitchen knives by hand. There is a lot to learn here, and my clients deserve to know the difference between my works and the works of others. They have a right to know about the best steels and designs, the best fittings and handles, the best stands, blocks and accessories. They should understand technically, artistically, and aesthetically why this is so. This is the purpose of this page as part of my Service Commitment to my professional trade.

A professional knifemaker's perspective is markedly different from a manufacturer's viewpoint, just as an accomplished chef's viewpoint differs from a line cook's. Additionally, as a maker of top grade weapons, tools, and fine instruments, my perspective is not the same as other knifemakers who use simple, antiquated methods to make knives.

If you are reading this, you deserve to know the distinctions. I'll do my best to lay it all out: the history, the reasoning, the technology, the direction, and the value. By the time you are finished reading this page, I guarantee that you will know more than most other people about truly fine chef's knives, more than most chefs, more than knife manufacturers, and even more than most knifemakers. While others may offer you baseless generalities, notions of great traditional histories, vague and non-specific ideals about their knives alongside tiny photos and very little useful information or specs, I will offer facts, specific descriptions, very clear and abundant evaluations and comparisons for your consideration. Armed with this concrete knowledge, I believe that you will be better equipped to purchase any chef's knife from any source for the purpose you intend.

You deserve a fine knife for your most important and frequent knife duty, task, and passion.

Thanks for being here!

Hello Mr. Fisher,

Thank you for your willingness to share your knowledge through your website. I have learned so much and have had my view on knives permanently

altered by the knowledge I gained from reading your website.

I will begin the same way as many of letters you receive by saying “Thank You!” Your website and the information you provide are extremely appreciated. Factory made knives are ruined for me now that you have provided a framework for me to logically think through what they are offering. I will admit that I was taken in by what you refer to as the “mysticism” of the knife industry until I read your site. I am a mechanical engineer for an aerospace company and as I read your site, all of your arguments were logical and matched to everything I had been taught in school. My whole perspective on what a good knife is has changed.

--T. S.

Great Knife..such balance no hand fatigue and sharp too.

With that knife in my kitchen. . . I am a surgeon--- not a butcher.

-- B. M.

A superior knife can create an exceptional meal and an extraordinary experience.

Newer kitchens are equipped with the best appliances, finest counters, floors, and walls, best modern lighting, sophisticated plumbing and sanitary equipment, and newest and most efficient modern cookware, well-designed tools, utensils, and accessories. At the forefront of every meal preparation with fresh, healthy, and delicious food is the knife. Chef's knives, meal prep knives, and kitchen knives are the most common knives seen. Every household has these kinds of knives, and they probably see the most duty of any knife.

The knife is where the meal starts, and I believe it should be the most durable, distinctive, and useful tool in the kitchen, because it is the tool that physically creates prepared food from raw meat and produce. One simply cannot be a chef without a knife. While a good chef can create a great meal with an average knife, a superior knife in his hands can create an exceptional meal and an extraordinary experience. It's about the chef's personal relationship to his knives. How the chef lives through the work of the knife will translate into how the meal experience occurs for others around him. The chef should be eager and excited about the prospect of putting his knife in his hand, working at his board, in his kitchen with his unique tools and appliances to create his distinctive meal. The use of the knife should be a flowing, fluid, and comfortable experience, and when it is, the preparation of the meal becomes a creative and wonderful event for not only the chef, but also his friends and family.

The tools and utensils of the modern kitchen are the most advanced and wonderful they have ever been in history. We are all lucky to be living in our modern world, and the chefs of the past would be astounded at what we have available in even the most modest modern kitchen environment. Though there have been a few new inventions in the culinary world, the major change in the world of the chef in historic times has been refinement. Meat and produce have been refined and cultured, cookware has been improved, and appliances have brought the chef out of the smoky fires of antiquity into the clean and efficient creation space of the modern kitchen. The cooking experience itself has been meticulously and accurately refined as art across many mediums and cultures.

Since the knife is the central tool of the cooking experience, it is important to be knowledgeable and well-informed about chef's knives. Thankfully, we also have refined our information technology to a high degree, and more detailed, specific and clear information is available from worthwhile sources to more people than has ever been available before in history. Right now, you are reading this because of refined information technology. The interpretation, direction, specifics, and art of knives is now available from metals artists and craftsmen like myself for anyone to see, at any time, in the privacy and time frame of their own personal choosing. I feel very lucky and thankful that you are reading this now, and want you to know that I have a great deal to offer based on my own practice, experience, and art in this field. I consider it an obligation and responsibility of the service aspect to my clients, my trade, and my art.

In my field, I have made many, many knives. Every knife I've made has been a refinement of at least one of several attributes. An attribute is simply a logic, quality, characteristic, property, philosophy, or character. On the surface this may seem a heavy group of considerations, but I want you to know exactly why handmade custom knives and my knives in particular are created the way they are.

Logic: My professional logic is that I want to create and supply the finest knives available in our modern world, with modern materials and techniques, to some of the finest chefs and clients, whether they are cooking at home, as a profession, or are determined to become fine chefs. I strive to create designs that are logical, for uses in the real kitchen, with reasonable and dependable geometries, materials, finishes, and accessories.

Quality: My standard is to create the highest quality knife, tool, and work of art that is possible using modern technology and process. Like my fine Tactical Combat Knives, I am determined to make only the very best. I use the highest technology modern corrosion resistant tool steels available, with modern and specific processes of heat treating, tempering, cryogenic processing, and testing with professional apparatus, in house, here at Sharp Instinct Studio. I use the most modern and refined fittings, designs, and finishes on the most durable handle materials possible for each knife. The fit, finish, balance and accuracy of each component is of the highest quality, and the excellence of the knife is matched by any accessory that accompanies it, so and my clients and patrons are assured they are acquiring the very best.

Characteristics of the fine modern chef's knife vary widely, perhaps more than any other type of knife known. Since there are many different processes that the chef's knife must complete, there is a great variety of blade styles and shapes, grinds and finishes, handles and forms. Chef's knives may perform delicate tasks requiring thin, hard blades, other chef's knives may need an improved and refined grip to apply great force with extended blade toughness. The characteristics of each individual knife determine which one you reach for in the block, sheath, or roll, depending on the task you have in the kitchen.

Properties of each knife distinguish them from others. For example, making a knife from modern high chromium, high technology martensitic tool steel distinguishes the knife from one made of 1095 or 52100 plain carbon steel by many orders of magnitude. The property of a gemstone handle distinguishes the well-made fine tool from a factory knife that has a polypropylene molded handle. Properties of fine handmade chef's knives instantly set them apart from mass produced knives in every way: materials, finish, design, balance, embellishment, fit, finish, accessories, and service.

My Philosophy of my chef's knives is unique. While every individual maker may say that his works and philosophy about the knives he creates is exclusive, I actually detail these specific distinctions on this very page, and on the 600 other pages on this very website for all to see. There is no mystery about why I make the knives I do or how I do it, I believe this field should be modern, transparent, evolving, and inviting to all who are interested in fine knives. One could boil down this philosophy quite simply: I am a full time professional knife maker, artist, and writer who does my very best to create the finest modern handmade knife and work of art for each individual client.

The Character of each knife, group of knives, or art project are what sets it apart as distinctive. No other knives look like or have the character of the knives I create, and that specific character appeals to each client, patron, or chef in a very personal way. The character of the fine, modern handmade and custom knife will prohibit it from ever being grouped in the endless clones of production work, replicas, primitive, or manufactured items, and exhibit the personality of the owner who appreciates finely crafted works of art as well as accurate and refined tools.

The only way to experience this personally is through a direct conversation. This is not available from manufacturers, boutique shops, and even other makers may not accommodate this. If you are interested in an extremely fine chef's knife or set, Email me here to discuss your project or idea!

Mr. Fisher,

It is just before midnight here in NYC, just walked in the door,

home from a long day at the restaurant. To my surprise was a FedEx

box waiting for me in the hallway. I am normally a pretty collected

individual, however I was like a kid on Christmas as I opened the box.

I am beyond impressed with the knife, it truly is a work of art

and great craftsmanship rolled into one. From the sheath, to the

balance of the blade, to the beautifully sculpted handle, I really

could not ask for more. You have a great talent and I thank you for

putting such time, effort and precision into this knife, it will be

cherished for a lifetime.

Thank you again Mr. Fisher.

Sincerely,

L. C. G.

Interest in fine chef's knives is on the rise. Most professional chefs are covetous of their knives and tools; indeed a fine custom knife set can personalize, identify, and distinguish a chef and his kitchen environment. Ask a professional chef what he most values and he'll probably tell you his knives. What kind of knives equip a custom kitchen or chef distinguishes his passion for the culinary arts.

You might also realize that most of the information about chef's knives is based in the past. Historically, extremely finely made knives were distinctly not chef's knives; the knives used to cook in the past were the cheapest, most common sort, made to use, use up, and throw away. Knives do not typically have a historic past of high value in culinary work. Since the very best knives ever made were either for recognition, dedication, or war, it's a new concept that extremely fine knives and accoutrements could be made for the kitchen. This new and exciting concept means that for the first time in history, knifemakers are using premium materials: extremely high alloy, high tech steels, clean, sanitary, and incredibly durable fittings, exotic or rare handle materials, extraordinary artistic blocks, stands, cases, rolls, and accessories.

You might wonder why top chefs are rarely seen with fine custom knives, particularly in public.

Extremely fine, well-designed and handmade chef's knives can be works of art. In my own works, every knife is absolutely distinctive, and every creation is first and foremost a cutting instrument. In the form of the knife, you will see the movement, feel the grip, sense the slice easing through the subject of your dishes. The very foundation of a fine chef's knife is the most substantial consideration that not only sets it apart in the realm of knives, but also offers the physical basis and traits that will establish its value. If you want to know the exact basis for the fine knife when compared to inferior knives, I've detailed the specifics in the next sections. As promised, by the time you have finished reading this page, you will know more about fine, handmade, and custom chef's knives than most other chefs, factories, or other knife makers!

Please read the wisdom box above again. This perception (a chef steeling a knife) is a persistent and cultural icon, often played in the media as a defining activity. When one sees a chef, he's wearing a double-breasted white jacket or smock, a white toque hat, perhaps an apron, and he is steeling a knife. This uniform dates back to French traditions; more on that later.

Why is he steeling his knife? Because it is dull. It starts out dull, and dulls easily, and dulls frequently, so he steels and steels and steels... After a while, he becomes pretty quick at the motions, and may even make it look effortless, like some graceful flourish before the cut. To a maker of fine custom knives, however, this action screams out, "Help! My knife is dull, it's continually dull, and I can't keep it reliably sharp!"

Sharpening a knife before every use is absurd. Do you honestly think that we are unable to make and offer extremely wear-resistant, edge-holding, instrument-grade tool steels in our modern world?

Consider this: a chef who uses a steel rod to bring up an edge is rubbing the blade's cutting edge across a roughened, often grooved piece of steel or ceramic. The steel rod itself becomes contaminated with whatever the chef was previously cutting, unless he has meticulously washed the knife blade with soap and water before steeling. The rod has bits of foodstuffs embedded in it and on the surface along with the metallic and abrasive particles of swarf. How often does the chef wash the steel with soap and water? Have you ever seen this done even once? Does he wipe it on a soiled rag that hangs on his belt? Where does he store the rod when it is not being used? How clean is it? Hmmm?

I consider it my duty as a maker of extremely fine chef's knives to help the chef out, but I can not help him if he has a low grade, inferior, and weak knife blade. The reason for every knife is the blade, and the blade is made of fine, modern tool steel (or should be). The fine knife blade should not be a low alloy, old-world style carbon steel, but the finest engineered, most modern, highest quality, refined, clean, and scientifically made and treated, machined, ground, and finished stainless tool steel we have available. In addition, the knife should always be made entirely of Food Contact Safe materials and construction. A good piece of professional chef's cutlery starts with the foundation of an exceptional blade. This doesn't only mean an ornamental blade, although style, appearance, and artistic value can be well-applied here.

Here's an email and a great question from a thoughtful reader of the website about my recommendation of Juranitch's book:

Subject: Contradiction about sharpening with steels

Hi Jay,

I am in AWE of your talents!

Could you please clarify one point for me.

In the subject: Blades: The Chef and the Steel Rod,

you seem to be unequivocally against the use of steels for maintaining a knife’s edge. You also strongly

advocate The Razor Edge Book of Sharpening by John Juranitch as the definitive source of information about

knife sharpening.

In his book, on pages 43-46, John strongly advocates the use of a steel for applying the finishing touches to an edge and for maintaining the edge.

This apparent contradiction has me confused and I’d be most grateful if you would clarify the situation for me.

--K. L.

Sydney, Australia

Hi, K. This is a great question, and I'll be happy to clarify. The short version is that the "Razor Edge Book of Sharpening" is a great basic primer, not the complete modern text on the subject.

Writing about this can be confusing because the word "steel" often refers to the rod used to "steel" the knife, which is a verb and a noun together, and can be confused with the steel that comprises the knife blade. So, in my answer here, I'll use the word "rod" to refer to the rod that a knife blade is dragged along, and I'll use the words "blade steel" to refer to the actual knife blade. Whew!

Juranitch published his book in 1985. You may see some other dates on the publishing, but these were reprints of the original text. I'm assuming he actually wrote the text before that, so let's just put it in the early 1980s. It doesn't seem so long ago to us older guys...yikes!

Back then, there weren't any high alloy hypereutectoid stainless steels being used in commonly accessible knives. Juranitch doesn't go into extremely high alloy knife blades; the book was written for the public at large. To this day, even if these higher alloy blade steels are being used, they are rarely heat treated to their maximum potential. So the first point is that the blade steels referred to by Juranitch are the more common, poorer quality blade steels, whether stainless or not.

This is not the kind of blade steel found in the finest knives, and this is the first difference in our modern knives. Truly, if a chef is dragging a blade on a rod, he is using a knife with inferior steel in blade alloy. Just as I wrote in this section, this is why the action screams out, "my knife is dull, and I have to continually drag it across this rod to keep it sharp!" That's the point here.

The second very important point is that when Juranitch wrote his book, there were NO good diamond stones available to the common man to sharpen a knife. On page 20, he briefly mentions diamond abrasives, but calls them expensive and too coarse. This is funny, because he never mentions the grit size he used. Back in his day, diamond hones were expensive, and only available in a few grit sizes (coarse and fine). They were also poorly made, bonded, and the crystalline structure of the diamond was not as sharp as today's. Currently, diamond hones are much improved in their method of manufacture and performance, they come in many different grit sizes (I have 8 that I use), and they are relatively inexpensive. Big improvement here.

Back then, in the early 1980s, our best methods of sharpening were to use silicon carbide, since it was the most durable and accessible abrasive to hone an edge. It would make sense if you were using a softer, inferior knife blade to sharpen it on a sharpening stone (or hone) first, and then keep it "tuned" with a rod. Juranitch himself claims that "steeling" (using the rod) is not a replacement for sharpening, and that blade sharpening must happen first.

The reason I recommend Juranitch's book is because it's what I consider the best text covering the basic elements that describe sharpening, mainly establishing the angles, relief, and the cutting edge. It isn't geared toward extremely fine high alloy blades; it was never written for the kind if knife you see here.

That is the point of this section. If your knife blade is so poor that it needs constantly dragged across a rod to keep cutting, it's a common, inferior blade. This screams out to the professional knifemaker that a better blade, one that holds and extremely long cutting edge, creates a better knife. The very best way to sharpen it is with a modern diamond hone. Being a better alloy, sharpening is kept to a minimum.

In the next topics, I'll cover the specifics of history, the myths of chef's knives, the technical realities, and the specific reasons I make knives the way I do. I promise that when you are done reading these sections, you'll know more than most people, more than most chefs, and more than most knifemakers about what constitutes the very best chef's knives and why. Thanks for being here!

Look around at what other knifemakers and factories tout as the best chef's knives and you'll notice that many of them recommend and use carbon steels. The term "carbon steel" is usually used to identify and distinguish steels that are NOT stainless. I'll assume that you first want to get this clear as to why these steels are used, why they have been used historically, and why they are claimed to be superior when they are absolutely not. In fact, carbon steels are inferior to high alloy hypereutectoid stainless tool steels in every single characteristic except three:

First, the name, carbon steel. All steels have carbon. All of them. This is what makes steel different from raw iron. Iron is the element; add carbon of enough percentage (a tiny percentage) and you will make steel from iron.

When knifemakers, machinists, and layman use the term "carbon steel," they are referring to plain carbon steel. Let's get very clear on what carbon steel contains, so that there will be no confusion: Carbon steel, according to AISI, SAE, ANSI, and machinist's and engineer's references is steel (iron with carbon) that contains manganese limited to 1.65%, silicon limited to 0.60%, and copper limited to 0.60%. That is the official classification for carbon steel. No other alloy elements are added intentionally. Clearly, carbon steels are low alloy, plain steels, without any beneficial ingredients (for some culinary language). Carbon steels are cheap, common, and plentiful steels.

Historically, this is how steels have been for about 4000 years. Only in the beginning of the 20th century have scientists and metallurgists started adding beneficial elements to this recipe to create alloys. The reason they did is to make superior steels; steels that have higher strength, higher wear resistance, higher toughness, and higher corrosion resistance altogether. Carbon steels are notorious for wearing quickly, dulling frequently, bending or breaking, and rusting at the first exposure to moisture. Add a little chromium to carbon steels, and they become harder, tougher, and more wear-resistant. Add enough chromium to the steels and they become stainless steel: resisting corrosion to a very high degree, adding considerable strength and beneficial wear resistance, and increasing toughness substantially.

If high alloy stainless steels are so much better in every way, why have knifemakers, manufacturers, and the public stuck with carbon steels? It's because they are selling a myth, and the public continues to buy it up.

For example, take a look at some major players in the kitchen knife and handmade knife world, and you'll see an almost mystical fascination with Japanese knives. You'll read and hear words like "mind," "body," and "soul," referring to ancient Japanese techniques and alleged superiority in knives and cutting tools. By the way, there is no Japanese superiority regarding steel, blades, or knives; there has never been; this is a myth. Knife manufacturers and some knifemakers love to use Japanese language and words to describe their blades, the features of their knives, as if Japanese is the only language that has words to describe these things. For example, the phrase "temper line" (originally described in English by John Yumoto in his technically detailed reference book The Samurai Sword written in 1958) is now called "hamon" only because the Japanese word hamon carries some mystique and exotic interest; it's still just a temper line. The phrase "temper line," after all, is so pedestrian...

This is typical of the myth, distraction, and fascination with a culture that is not distinctly known for fine culinary practice. If someone asks you what culture was historically known for the finest culinary refinement, chances are you would answer, "The French!"

So why is it that Japanese-style knives and cutlery hold such a mystique for Americans? It all stems from the association of Japanese swords, knives, and weapons that were removed from Japan as it was disarmed after the end of the second world war. Our grandfathers and fathers brought home many of these weapons, and marveled at their construction, even though they were poorly made. This is the essence of knife myth; knives, swords, weapons, and tools acquired after battles, imbued with almost reverent awe, completely undeserved in materials and construction. Tales are told, conquests embellished, interest is piqued, and before you know it, later generations of the American culture is pushing out movies and entertainment featuring magical Asian swords and feats of ridiculousness.

Know that as early as 1950, there were more Japanese swords in the United States of America than had ever existed in Japan. This is cultural fascination, originating in the warfare history of the national treasures of Japan, repackaged by Hollywood, the media, and knife makers and knife manufacturers, and sold as some unique, superior concept and product. Media and entertainment marketing interests have even attributed myths originating in other cultures to the Japanese. Myths based on fantasy? Read "The Sword, the Veil, the Legend" page to understand how all this happens.

The truth is, every single culture on the planet has created good knives and dishes, bad knives and dishes, and every type in between. Isn't it interesting that since most mass-marketing comes from the Asian east, Americans tend to adopt that particular style as technically superior, when this has absolutely no basis in historical or contemporary reality?

The Japanese did have advanced techniques for working with steels and producing effective weapons a thousand years ago. So did the Indians. So did the Persians. So did the Chinese. Today, the very best steels are found in the industrial, military, and scientific field. Please don't buy the hype promoted by media and Hollywood, repeated by knifemakers who hammer steel, no matter on what public outlet their "spiritual journey" is sold. Every single culture on the planet produced and used kitchen and chef's knives, yet somehow, here in America, there is almost a worshipful embrace of a failed, long-past 1000 year-old foreign Japanese culture.

There is no blacksmith in any machine shop, anywhere.

I prefer truth to mysticism, and the truth in steels can be found in the most advanced, modern technological, scientific and sophisticated metallurgy in the history of mankind. If ancient, well-documented steel and blade-making techniques were superior, we would see them used in modern industry, where shear blades must cut thousands of miles of tenacious abrasive material, where car bodies must be sheared and pressed, where molten plastic must be injected into forming molds at incredible speeds and volume, and where ball bearings have to pump liquid oxygen into rocket engines.

But nowhere, NOWHERE, is there a blacksmith in any machine shop; nobody is pounding away at layers of different steels to achieve improved performance, because it doesn't. Nowhere in the professional field of metallurgy is any engineer touting the advanced technology of any country in 1600 AD. There are no helicopter gears, machine cutting tools, aerospace tooling, turbine blades, crankshafts, valves, milling cutters, or any significant metal piece that must be hard, wear-resistant, tough, and durable that is made of carbon steel or is hammer-forged.

It's time this myth was put to rest. It's an embarrassing artifact of our tradecraft, and it needs to stop. The only advantage of using carbon steel is because it's cheap and not wear-resistant, so it's easy to steel up an edge with no effort, an edge that quickly wears away (and rusts) and needs to be steeled and sharpened again and again, and again. Carbon steel and low alloy steels are food-unsafe, dirty, weak, corroding steels and their use needs to stop in the kitchen.

Hello Jay,

The Andromeda K2 Azurite arrived a few minutes ago. It is stunning. I think the photos do not at all do it justice, even though they are very good photos.

I have a couple of 10x loupes for close inspection work, along with some daylight illumination for good color rendition, and spent a few minutes

admiring the K2 Azurite. I have never seen anything like it. Very beautiful, much more so in direct examination than in a photograph.

The sheath complements the knife very nicely. It is a real work of art.

Thank you very much for making and selling such a wonderful knife to me.

My best regards,

--R.

The people who push carbon steel and damascus knives do not want you to know that the reason a lot of cooks like them is that they are easy to sharpen. That's it! They are easy to put an edge on because the steel is not wear-resistant, not tough, and not abrasion-resistant. It is easy to hone up a fast edge with no skill. The low-information cook will then go on to claim that carbon steel and damascus blades are better, because he can get an edge on them easily.

He needs to do this often, because his blade dulls quickly. He grabs a dull blade, flourishes it across the ridged steel rod, feels that he is now a pro, and goes to cutting. It would surprise him to know that if he upgraded to a premium steel, he could throw away his rod, stop honing, and sharpen his knife once a year or less, and it would always be razor-keen. But then, would he feel like a chef if he didn't have to hassle with the knife blade: honing, wiping, oiling, scrubbing, drying, babying, coddling, and fondling his knife? Or, maybe he just whips the dirty blade on a dirty steel rod, and goes to cutting your food...

The truth is, if a knife blade needs steeled and sharpened often, it dulls easily. If it dulls frequently, it's soft and not wear-resistant. If a knife blade is hard and wear-resistant, it doesn't need constant sharpening or attention to the cutting edge. If a knife is hard to dull, it's hard to sharpen, usually needing diamond hones. If it's easy to sharpen, it's easy to dull, and any old rock or piece of steel will do to get a bit of a temporary cutting edge on the blade.

Who would know this and say, "I like to sharpen my blade often; I need a soft blade that I have to constantly work on to get it to cut correctly. I'll have to worry about cleaning the blade, and cleaning the rod, and storing it all together in a clean place."

Who would say, "I like to pick up my knife and simply cut with it, without worrying about the edge, and focus on preparing my meal."

Which person are you?

More about this sharpening fallacy on this topic on my Heat Treating and Cryogenic Processing of Knife Blade Steels page.

The people who push damascus steel blades do so because they like the look. The look is different, they think the blades are pretty, even though they are inferior in every single aspect and characteristic to high alloy stainless tool steels. They are selling a look, not performance. The only advantage of Damascus pattern welded steel is appearance, all damascus pattern welded steels are inferior in every way to high alloy hypereutectoid stainless steels. More about the severe limitations of damascus pattern welded steel at this link on my Blades page.

Never mentioned by makers of carbon steel knives, the cutting edge corrodes away with every use and exposure in the kitchen environment.

Thus, the steel rod...

Knifemakers tend to defend their use of the carbon steels and low alloy steels in the kitchen. When you have and use a non-stainless knife blade in a kitchen environment, the blade will corrode. No one likes the word "corrode." It's a rather abrupt and uncomplimentary word, and means to destroy or damage by chemical action. This is exactly what happens to knife blades in the wet, acidic, or alkaline environment of the kitchen. When carbon steels corrode, they start by a darkening in the surface which is obvious and ugly and can continue to uncontrolled rust. Worse and never mentioned by these makers, the cutting edge corrodes away with every use and exposure in the kitchen environment. Worse, not a one of these steels is a Food Contact Safe material!

Knifemakers know this, and so does everyone who uses a carbon steel knife in the kitchen, but they don't like to admit it. The surface is corroded, but this sounds too harsh. So they opt for a more gentle term. First, they might use "oxidize," but still, this suggests some corrosive action, so knifemakers have settled on the term "patina." They slather mustard, coffee, vinegar, bleach, and ferric chloride on their blades, looking to find an easier way to "pre-corrode" their knife blade into a so-called patina, so it won't look so bad in the kitchen.

I'll get more into this later, but here's the really important thing: the surface of a steel knife blade reacts with its environment. If you choose a carbon steel or low alloy steel, you will have do deal with corrosion. Call it a patina, call it oxidation, or call it corrosion: it will react, it doesn't care what you call it, and it won't stop.

Knifemakers who use these steels often spank the knife owner for not oiling, wiping, waxing, babying, coddling, and fiddling with their blades when the owner complains of rust. They try to make the blade deterioration the customer's fault, claiming he or she doesn't know how to "take care of" a carbon steel knife. This is well-known and common in our trade, and it's insulting and ridiculous, since the maker is at fault for selling an inferior, corroding, rusting, and highly unstable knife blade with steel that easily reacts and corrodes—for use in the kitchen! This would be like selling a carbon steel knife blade to a US Navy SEAL Team member that will use it in the jungle and in saltwater marine environments, and then telling him it's his fault for the knife rusting! Carbon steel is the wrong steel for anyplace wet, including the kitchen! This is the most hideous failing of modern knifemakers, and it goes on and on.

The worst part? How about the guy who sells distinctly food contact unsafe $10,000.00 to $20,000.00 carbon and low alloy damascus forge-welded steel blades for kitchen use, and they rust and corrode at the first exposure? He tells his clients to wipe the blade between uses with a cloth (hey, why does my fruit compote taste like fish?), and then goes on to claim that the patina (oxidation and corroded surface) will protect the steel (no, it won't). And since it clearly doesn't, he goes on to tell the client to scrub the blade with ScotchBrite®, detergent, Comet®, and Bon Ami® abrasive cleansers to remove the rust. Hey, what happened to my "protective patina?" Then, he goes on to sell his clients a "Home Polishing Kit" and a "Carbon Steel Cutlery Care Kit" for an extra kick in the pants! What's in these "care kits?" How about this, for your $20,000.00 blade: a can of WD-40®, and some sandpaper. Get to work!

Then, when you're done, you can spray your blade with Camellia oil he sells for some exotic flavor. What is camellia oil? It's tea seed oil, extracted from the seed of the tea plant. It's a fatty, organic oil that will go rancid, particularly when left in open air. Helpful hint: mineral oil will never, ever go rancid.

No wonder so many chefs and professionals think knifemakers are uneducated hicks.

Or, you could just get a knife that has a blade made of more wear-resistant, tougher, longer-lasting and premium high chromium high alloy food contact safe stainless steel that won't ever darken, corrode, stink, or rust in your kitchen. You could sharpen it less often, clean it with soap and water, and put it away without worry.

Gee... hard choice.

Jay,

That is so unbelievably beautiful, I am at a loss for words. The downside of museum quality

is that it belongs in a museum for everyone to see and I will no doubt feel a little guilty using

this to chop produce. But I will not deny this work of art its purpose, so I shall definitely

put it to work.

—Later—

Jay,

Looks like a dream, cuts like one too. Has transformed the tedium of a marathon of holiday cooking to a joy!

--A.

I dare you. Here is what other knifemakers, companies, and manufacturers of carbon steel knives don't want you to ever know!

I take no responsibility for any injury that may occur during this test! If you don't have good motor control, and can't follow simple, logical instructions, do not perform this test! If you are super sensitive to taste, do not perform this test! In fact, if you have any trepidation at all about this test, simply read this section and learn.

If you really need a clear demonstration of the limitation of carbon steel (non-stainless) to prove it to yourself, I've developed a simple test. This was not done with technical help from metallurgists, research scientists, or promotional and advertising professionals. This was developed in a simple moment, with logic, common sense, and clear intent.

After you perform this test, you will never, ever again consider carbon steel of any kind for food service, for exposure use, and possibly for any knife, unless it's surface treated or hot-blued. Even then, you won't want it in the kitchen at all, ever again in your lifetime! You won't want your meal prepared by anyone who uses a carbon steel knife, you will seriously avoid those sushi bars where the chefs slice up raw fish and vegetables with a dark, funny-shaped thin carbon steel Japanese-named knife with a straight handle and a stick tang. You might even start asking your butcher, favorite restaurant owner, and accomplished chef what they use for a knife, only to correct them by suggesting this very test! You think I'm exaggerating?

Read on and pay strict attention; I'm about to change your perception of carbon steels forever!

That's a pretty bold claim, and you might think I'm just trying to sell you an idea, but here's the thing: you will make this transformational decision by yourself, once and forever, and you'll never go back again... ever. Your own experience will be so profound that you will show others. Others will be transformed, instantly. My only request is that you properly credit me for this test by using my name, Jay Fisher, and maybe even include my website: www.jayfisher.com in your repeating of this test.

You don't need any special equipment for this test. You will need a few basic items that you, no doubt, have, since you are reading this text:

Take both knives to the sink, and clean them well. Use soap and water (anti-bacterial or dish soap is common and accessible, and what you would be washing the knife with anyway). Be careful not to cut yourself, scrub the blades clean of any oil, fats, or greases. This is just like cleaning your silverware or cutlery in your own kitchen. Of course, be careful of the cutting edge; you don't want to slice your finger. Get the blades as clean as possible, just like your silverware. Dry them.

The test:

Spoiler alert! Don't read this before performing the test if you want to experience the full effect!

Here's what will happen: Your tongue will start to salivate as the carbon steel reacts with the moisture. You will feel an astringent pull—kind of a dry chemical reaction—before the ever-increasing glow of full iron overwhelms your entire tongue surface in contact with the steel. The bitter iron taste will be strong: stronger than blood when you bite your lip, stronger than you will ever expect. The iron will permeate your tongue, and dry and sour the entire surface of your tongue for at least 30 minutes after you've pulled away in utter disgust. You will slobber, you will pucker, you will hate the taste that is now stuck on your tongue. It's as bad as being burned by hot coffee in a hasty sip, worse than any bad cheese or salty lemon you have ever experienced. You will absolutely hate it; it won't go away until your mouth is fully rinsed and cleaned! The taste effect may literally last for hours! I could still taste the corrosion after 8 full hours and several meals!

Your conception of carbon steel blades will be changed forever and instantly, and you will thank Jay Fisher.

Now, test the stainless knife. Heck, you don't even need a knife, because this will be the same as putting your mouth on your stainless silverware. Nothing will happen. You'll be surprised that there is no taste, no flavor, no iron, no reaction. This is why we have stainless steel cutlery, after all.

What has happened and what it means: The moisture in your tongue along with oxygen in the atmosphere has reacted dramatically with the surface of the carbon steel blade. The steel has immediately broken down in a chemical reaction, producing iron oxide which is essentially rust. The oxygen aided by moisture combines with the metal at a molecular level, forming a new compound called an oxide and weakening the bonds of the metal itself. Rust consists of hydrated iron(III) oxides Fe2O3·NH2O and iron(III) oxide-hydroxide (FeOOH, FeOH3). Surface rust is flaky and friable, and it provides no protection to the underlying steel. You are eating rust, and rust is now bonded to the surface of your tongue. You will probably experience temporary dysgeusia, a distortion of the sense of taste. Dysgeusia (dis-goo-see-uh) is not a pleasant experience, but it will go away.

If you don't clean your tongue-mark off the carbon steel blade, and revisit it in a couple hours, you'll see the contact area in clear discoloration. Sometimes, this only takes minutes. Since rust is permeable to air and water, corrosion will continue. Left alone, overnight, the steel will start to darken more, in another day, you'll see microscopic flakes, followed by pitting.

If you really like the taste of your carbon steel blade, let it pit and flake and start to dissolve into corroded flecks and then use a wire brush to sprinkle them on your cereal, or perhaps your cappuccino, hot dog, or steak. Nice fall colors can be presented over potatoes, a kick can be added to your chilled watercress soup or your mango-lime cheesecake.

If you think I'm being overly dramatic, and realize that chefs and cooks have been cooking with carbon steel blades for centuries—so why would Jay complain—think of this: since the dawn of stainless steels, all table cutlery has been made of stainless for a reason. Sure, there are some gold and silver spoons and forks, and they don't have a reaction with your tongue, either. Nobody is eating with an iron spoon, nobody is using a carbon steel fork to lift their cake to their mouth, no butter is padded onto toast with a carbon steel butter knife. There are no carbon steel cutlery sets for a reason, and because of this test, you now know why.

Why do people still use disgusting carbon steel knives for food?

In man's history, stainless wasn't available until the early 20th century, and then, it wasn't wear-resistant and good for cutting, so we were still stuck with carbon steel knives. That all changed in the latter part of the 20th century, and now we have incredible stainless steels, far superior to carbon steels, but no one has told the chefs, or they simply can't afford them. They naïvely haven't moved into the 21st century, the one where we have the finest stainless tool steels ever to exist in mankind's history. In some cases, they are buying the Japanese "superiority" complex, where hammer and black scale are considered the normal knife finish, because it looks old, and so must have been made by an ancient samurai warrior—corroded and black and foul-looking.

In other words, it's just plain ignorance or bad habit to be using carbon steel knife blades in the kitchen.

Corroded, blackened, or even simply darkened carbon steel is not "protected" by the corrosion, no matter if you call it a patina, an oxide, or a surface finish. If you think carbon still is protected by the oxide, just wet the surface of a darkened blade, rub it a little and smell it. It's not as shocking as the taste test, but you'll understand exactly what your nose is telling you.

The reason for all of this chemical effect in carbon steels is that corrosion instantly occurs upon exposure to air or moisture, and it's detrimental to the dish, the food, and the palate. A knife slicing through a piece of fish may well move fast enough to not flavor the fish with corroded rust, or you may have just gotten used to the hint of steel, so slight as to not be perceived. Perhaps the nasty flavor is overwhelmed by the taste of the fish, but it is still there.

Worse, the carbon steel is corroding at the cutting edge. It's dulling and dissolving quickly and at every slice, so the chef or cook is constantly scraping his cutting edge on a hard steel or porcelain rod, which flakes off the corroded surface (swarf) and deposits it wherever it can. This can be on the surface of the knife blade, on the next piece of food cut. Or it may be on a nasty rag the chef uses to wipe off the metal swarf hanging from his waist or draped over his shoulder.

One more important thing: the test you performed was with the moisture on your tongue. The pH of your saliva is about 5 to 7, slightly acidic. What do you think happens when carbon steel blades are use to cut tomatoes (3-4 pH) or lemons with a pH of 2? How fast of a reaction and how deep the corrosion then?

My point here is... WHY? Why do this when fine, better-made high alloy stainless steel blades are available, and they don't react, rust, pit, stink, or sour your food? Why are makers and foreign (Japanese) knife companies pushing carbon steels?

They are doing it because it's cheap, fast, and easy to make a knife from carbon steel, and you can whip up a cutting edge with a chef's steel (rod) quickly since the blades are so soft to begin with. A good, high alloy stainless steel blade needs to be sharpened only once a year or so, a carbon steel blade once a day (or session).

One more important thing: this very test, the reasons that you can taste carbon steel, the corrosion and dissolving of the metal is why CARBON STEEL IS NOT A FOOD CONTACT SAFE MATERIAL! Please read why the USDA, FSIS, CDC, ASTM, and other agencies very clearly declare that all carbon steel knife blades are NOT FOOD SAFE.

Don't fall into the carbon steel trap! Do the test, make others do the test, impress your friends and family, and be done with carbon steel knives, particularly in the kitchen, the most knife-important place on the planet!

I dare you.

Let's get into the details of why and how modern alloy stainless steels are better choices overall:

Clean, modern, high quality martensitic high alloy stainless tool steels are the best choice for fine, well-made, and durable chef's knives.

Carbon steels and damascus steels are not a good choice and there are several clear reasons. Plain carbon steels will quickly and easily rust if not meticulously cared for, and that level of care doesn't happen in the kitchen. What are the bad carbon steels I'm writing about? 1025, 1045, 1085, 1095: these are all low alloy plain carbon steels that are inferior to fine high alloy steels by many orders of magnitude and on many levels. Carbon steels corrode, and the steel that corrodes away goes somewhere, usually into the food. Because the entire blade corrodes, that means that the cutting edge also corrodes, so they dull faster. This is why they are not food contact safe.

Carbon steels often have a greater following because they're the cheapest and easiest to make a knife with, they are forgiving of process errors, and they are cheap to replace if any part of the knife making process fails. They are cheaply purchased, commonly available, and easily ground, easily machined, and easily sharpened. A few well-angled whips over the steel is usually all it takes to sharpen them, and this has to be done often, since they dull so quickly. This is why you so often see the chef reaching for the steel. So the misperception is that carbon steel blades are better, because they seem to sharpen easily, and seem sharper. Why do they sharpen easily? Because they are low alloy steels, and are less wear-resistant and dull quicker!

Standard carbon steels contain none of the alloys that allow the creation of chromium carbides, tungsten carbides, or vanadium carbides that are the extremely hard particles in the structure of stainless tool steels that give these high alloy steels such substantial and profound wear resistance and strength. Carbon steels are not as strong as high alloy stainless steels.

What about alloy steels that are commonly used by knifemakers? Steels like 5160, 52100, and other alloy steels are low alloy, low carbon steels. 5160 has less than 0.7% carbon, making it hypoeutectoid and unable to form complex carbides. It has a little bit of chromium (less than one percent) which helps with hardening somewhat, but not enough to perform well as a knife blade. 52100 is a better steel, and with about 1.0% carbon and 1.5% chromium, it makes a good ball bearing steel, but is vastly inferior to high alloy stainless steels. And, of course, neither of these steels has enough chromium to offer any corrosion resistance whatever! They are also NOT FOOD CONTACT SAFE!

If corrosion resistance is important, why not opt for stainless steels only? It's because not all stainless steels are the same—not even close.

Note that I refer to stainless tool steels, as not all stainless steels are durable and wear-resistant. Stainless steel for chef's knives got a bad reputation in the 1960s and 1970s due to the cheap 420 series stainless blades that were sold as bargain, universal, forever-sharp knives. They're still sold as such, and they are simply thin, weak, stainless springs, and not tools. Steels like AEB-L, 19C27, and 15N20 are also low alloy stainless steels, not the premium steels for knife blade use. I detail this more in the topic below.

Fine, high quality, high alloy hypereutectoid martensitic stainless tool steels, when properly hardened and tempered, will hold an edge many times longer than carbon steels, will not corrode, rust, pit, or stain, are much tougher and more resistant to breakage, and can be made thinner at the cutting edge than standard carbon steel knife blades. They are also many times stronger, with markedly greater tensile strength, shear strength, and compression strength.

What are these fine high alloy martensitic stainless tool steels I'm referring to? 440C, ATS-34, CPM154CM, CPMS30V, CPMS90V, CPMS35VN, CTS-XHP, BG42, and D2. Remember that these modern, isotropic, homogenous, refined and engineered steels are used for extremely wear-resistant, corrosion-resistant ball bearings, valve seats, high speed metal cutting and forming blades, and injection mold dies. They are used in industrial, military, medical, and mechanical field high strength, high wear applications because they out-perform all other steels. If standard carbon steels were better performers, engineers and machinists would be using them for these extreme applications. They don't because they are inferior steels, plain and simple. Please think about that. There are more details about these knife steels on my Blades page.

The most important, scientifically controlled, accurate, and technically proficient process performed in the knife making studio is heat treating. Proper heat treating is what makes the steel blade excel in performance, durability, longevity, and value. Heat treating, at first glance, seems to be a simple process. In the very best technical execution of our art and craft, it's a lengthy, detailed, and specific set of steps requiring a sophisticated shop and studio environment.

Heat treating by novices and factories can be a very simple affair. In any blacksmith's shop, a piece of steel can simply be heated to red, quenched, and reheated to a lower temperature, judged by the color of the oxide surface on the steel, by eye, and the steel will be harder than it originally was. This has been done for millennia, and is common practice in third world blacksmithing operations. These operations are limited to low alloy steels by necessity, and that is why smithing is an antiquated craft. No modern machinery anywhere uses blacksmithing techniques when extremely high performance is expected and required.

Factories (particularly foreign) making knife blades may use similar techniques, but with automated machinery to heat up the steel, and quench it in an assembly line. They choose simple heat treating methods applicable to unsophisticated steels, to suit their automation and production lines. They also choose cheap and economical methods to heat treat the steels; no factory is going to use complex heat treatment regimes with advanced steels, because that is not within the cost margin, scope, or profit margin of their production line and delivery schedules.

This is not how the best modern blade steels are treated, and the results are that when properly accomplished, the condition of these steels are tremendously enhanced. These improvements are across the board—strength, wear resistance, toughness, corrosion resistance, asperity reduction, fracture resistance, and microstructure are all improved by technically applied heat treatment and cryogenic processing. So significant are the improvements that yearly sharpenings (or less) are usually all that is required to keep the knife blade razor-keen. The custom knifemaker, then, is also the custom heat treating shop and there should be no question about his experience.

On one knifemaker's site, I smiled when I read the maker claimed he had a 6 hour heat treat process comprising of 7 steps. This is a laughable, inferior process, and I can tell that just from his simple description.

My clients deserve to know exactly what happens during heat treat, what the advantages are of my processing, what is necessary and recommended for each steel type, what to expect from the detailed processing, and how it all happens. This is available on my "Heat Treating and Cryogenic Processing of Knife Blade Steels" page here on the website. A typical processing of a high alloy martensitic, hypereutectoid stainless tool steel takes 15 actual steps, and 95 hours. I take my heat treating very seriously; it's a major part of the professional knifemaker's responsibility.

In 2018, I started performing an extended T3 heat treating process on my select premium blades. This new advanced process takes 30-33 steps and 172 hours!

Evening Jay,

I wanted to give you a proper testimonial now that I've had time to use Sirona at work for a day.

I couldn't wait to bring out Sirona at work, everyone noticed the shining mirror polish immediately

while I was getting ready to small dice about 150 tomatoes to keep the restaurant stocked for the day.

Sirona was well up to the task. The knife felt like an extension of my hand, and the extra weight

also feels good, knowing that I'm not using some flimsy piece of carbon steel that I'm so used to.

After seeing in person how good a knife could be, my first thought was that I can't wait to order

my next two! It was a pleasure to speak with you on the phone and I look forward to doing business

with you in the future.

--A.

The part of the knife blade that thins the steel to create a cutting edge is called a grind. Some people and sources call this a "bevel," but a bevel is defined as simply the slant of a line. It doesn't apply because not all knife blades have linear, slanted, flat lines that create the cutting edge, but all of them are ground. So modern professional knifemakers call this a "grind." Novices call it a bevel.

The grind of a knife is extremely important to the chef's knife. If the blade is thick at the spine, or back of the blade, it means that the blade is extremely strong, since a thick spine translates to high strength. Depending on the geometry, the intended use of the knife, the design, the steel choice, and the strength, the maker may choose different grinds to achieve a thin blade at the cutting edge.

The hollow grind, when well executed, creates the thinnest cutting edge that lasts the longest time, when the blade stock is thicker at the spine. When you think of the words, "razor-keen," you are undoubtedly referring to a hollow-ground straight razor of old. The hollow grind is detailed and described, and compared with flat grinds and convex grinds on my "Blades" page at this bookmark. In that section, you can easily see why a hollow grind has such longevity and thinness at the cutting edge, and why it's considered one of the best grinds. With a thicker spine, the hand can be used to apply pressure to the cut without digging into the heel of the hand.

The flat grind is also used in chef's knives, but only when the blade is very thin to begin with. In knives that are less than 1/16", (.0625", or 1.5mm) thick at the spine, a hollow grind can not be accomplished, and wouldn't be of a benefit. So these knives are typically flat ground. The flat grind is usually a long, continuous grind to the spine of the knife, without thinning the spine and weakening the blade, particularly at the blade-to-handle junction, the ricasso. One of the drawbacks for a thin, flat grind is that the thin spine can be uncomfortable to use if bearing down and applying pressure with the heel of the hand. So flat-ground knives are not typically used to apply pressure with the heel of the palm on the blade spine.

Something that is usually overlooked by knife buyers that it is far easier and cheaper to flat grind a knife with automated equipment than to hollow grind and mirror finish. The same can be said of unskilled labor. A flat grind can be done completely by machines and jigs and untrained hands, but the hollow grind can not be, particularly when both types of grinds are finely finished. Any machine can do an initial rough grind, but not a finished grind. Without going into technical specifics, I'll say simply that machine finishes of flat grinds are simpler and cheaper, and manufacturers know this, and extensively hype flat knives to keep their manufacturing costs low. Consider this: there are several firms that sell blade stock pre-ground into flat beveled shapes to further cheapen the manufacturing process. Also, a very thin piece of steel is cheaper overall, so the investment in materials by the manufactures is lower.

A flat grind often has a problem of foodstuffs stick to the flat side of the blade because of surface tension, and the hollow grind can allow air to come between the steel and the material being cut, allowing a cleaner release. Addition of milled holes, slots, and surface texture may help both knives.

In either case, the purpose of the grind is to thin the metal blade so that a fine cutting edge can be created by hand-sharpening. If a blade is too thick, the knife user will often tilt up the spine of the blade when sharpening on a stone, creating a less than optimum angle that does not aid in slicing. A thin blade grind, a low angle sharpening, and very good blade steel properly treated will offer the very best performance.

Both hollow grinds and flat grinds have their place, some of my clients request both.

In most applications, the chef's knife blade must be hard. In knives, the term hard is a not a generalized description, but a specific number (Rockwell), based on the ability of a diamond or carbide point to penetrate the steel when pressure is applied by a calibrated, scientific instrument called a hardness penetration tester. Details about this process are on my Blades page at this bookmark.

When a knife of fine tool steel is properly heat treated and hardened, the high hardness translates to increased wear resistance. If the heat treating and cryogenic processing is performed in-house under the maker's control, he can assure that the proper hardness (and wear resistance) will exist throughout the blade's geometry, and that repeated sharpenings will always yield a hard and wear-resistant cutting edge.

This is where factory knives fall flat on their face. Factories do not use steels that can be both hard and tough, so they settle for tough. Like a spring, they will flex, but not break. But they will dull quickly, and are usually left and used dull, or constantly need steeling to be sharp. This type of knife is one that requires frequent honing on a steel, but a hard knife will be wear-resistant and hold an edge longer, require markedly less sharpening, and therefore last many, many years longer, even for generations!

Who chooses a soft steel? Who wants to constantly baby and tend the cutting edge, abrading it on a steel or ceramic rod, whipping, stroking, and worrying it into shape?

Conversely, who wants to simply pick up their knife and prepare the meal, day after day, reliably and immediately?

The chef's knife blade must be tough. Toughness is resistance to breakage, or literally, the ability of the crystalline structure of the steel to be ripped apart from itself which is a fracture. For a knife to be tough, it has to be tempered back from full hardness, but tempering a knife back can reduce the hardness and wear resistance. This is another reason for a careful steel choice and accurate heat treating.

Only high alloy steels are capable of being both very hard and very tough when properly heat treated and tempered. This is also a reason for the heat treating to be performed in-house at the knife maker's studio, shop, or establishment. That way, the temper of the knife is created by the maker to his standards and his client's standards for the specific knife requirement, and accurately tested with calibrated instrumentation for certainty. Factories and manufacturers usually temper a blade way back, into the realm of softness and flexibility. Most factory chef's knives are softer than a wood saw. softer than a sewing needle, and many are softer than a box cutter blade. They want the blade springy, so that if it is somehow bent severely, it will not snap.

What experienced chef would ever bend a knife this way? He would know better, so the reason this is done is for the general public. The price of having a springy, bendy knife is loss of hardness and wear resistance. This translates to frequent steeling and sharpening, a short blade life, and an inferior edge. But then, there is the planned obsolescence as the cheap, soft knife is used up and the factory depends on repeat sales.

Some blades can be purposely designed with a bit of flexibility. Boning knives and fillet knives are sometimes created this way so that they can form to the cut using the force of the hand through the meat. Proper deep thermal cycling in the heat treating and tempering process can yield the blade that has limited flexion, while maintaining high wear resistance. This custom treatment is only available from a knifemaker who heat treats his own blades. For more about flexibility, elasticity, and stiffness in knife blades, please take a look at this dedicated page.

There are a bewildering number of blade shapes for chef's knives, and this is a good thing. Every task in the kitchen is different, and every chef is different, so it makes sense to offer a variety of knives to the chef. In fact, the chef is the one type of client I have that requires many knives of different designs, suited to his own personal preference, style, and passion.

While a factory and many other makers only offer a small group of similar knives based on their limited manufacturing ability, a true custom knife maker will offer a wide, ever-growing assortment of knife blade shapes. There simply is no singular knife for all tasks and requirements in the modern kitchen and the maker should work with the chef to build a knife to his specific personal needs. This is why I have over 450 different patterns of knife, and add new patterns in every batch. Where will you go to see that many patterns or have custom designed the knife of your choosing and particular needs? This is the realm of an experienced custom knife maker alone.

The neat thing is that as the field grows, so does client and chef's input. While chefs do not have any say in what knives are offered by factories and most other makers, a true custom knifemaker will work with their clients to get them the type of knife they desire. In blade steels, the custom knifemaker is the singular person who can and should answer any question the chef has about his blade steel choice.

There is a reason that medical equipment and tools are clean, brightly finished stainless steel.

The chef's knife must be kept clean, and be able to be kept clean. You understand by now how standard carbon and low chromium steels can corrode, rust, and pit, eating away the metal on the cutting edge and on the surface of the steel. These same steels can corrode underneath the bolsters, guard, ferrules, fittings, and handle material: unseen, until an absolute failure of the knife blade, tang, or handle.

There are also other considerations. In many hand-forged and handmade knives, as well as most of the Asian cutlery from Japan and China, finishing is ill-considered, hasty, cheap, and fast. I cringe when I see so-called chef's knives with a finish that is crusty, hammered, scarred, gouged, dented, dark, beaten, and scoured. Most people think that this is done to show some hand-crafted nature of the piece, giving it a primitive look, linking it in concept to some ancient master toiling away at his bellows and coal forge high in the mountains of east Asia (or Appalachia).

The reality is quite different and frankly, sad. This is a dirty finish. This type of primitive finishing is fast, easy, and requires no skill whatsoever to do, and is simply a cost-cutting measure for the knifemaker or factory and of no benefit to the knife owner. The whole idea of making a knife look crude and "handmade" by beating the surface with a hammer is prevalent in mass-manufactured Japanese knives. The huge and looming problem is that these are unclean finishes, they trap and hide moisture, grease, bacteria, fats, foodstuffs, fungus, molds, viruses, and all sorts of nasty things you don't want on your knife blade, and ultimately, in your salad.

A chef's knife has to be able to be cleaned and kept clean. Though a mirror finish on the blade is best, a very fine satin finish will also provide a smooth, cleanable surface that prevents or inhibits bacterial and other growth. Why do you think that professional counters, pots, pans, implements, tools, and objects in the restaurant and medical field have satiny smooth and cleanly mirror or polished finished surfaces in a high chromium steel? You've got to be able to clean them, that's why. This is the same reason that medical equipment is clean, smooth stainless steel.

While a primitive look may go well when hung on a wall as part of a crusty, primal decoration, it does not serve the chef where he preps, cooks, and serves. Would you cook in a pot that has a dirty, scarred, crusty, blackened, and pitted finish? Would you serve with utensils and expect people eating your meal to have dark, pitted, stained, crusty, and rusty cutlery and silverware? Of course you wouldn't, there is absolutely no advantage to the primitive finish whatever, yet you see it on knives all the time. This needs to change in our tradecraft. The chef's knife should be the cleanest type of knife made.

Another consideration is fracture. Metallurgists, machinists, engineers, and scientists know well that all fractures start from surface imperfections. This should then make you consider why anyone would encourage the weaker multi-weld layering of pattern-welded damascus when durability is paramount. More about that here. Why saddle a client and chef with a steel that starts out with surface defects that can encourage this?

If you are a fan of a dirty blade, go ahead and offer your guests stained, corroded, and pitted silverware, scarred and discolored plates, and maybe dark and rusty cups and other utensils. See how they like it.

Doesn't make a lot of sense does it?

Endurance of the chef's knife or well-made kitchen knife blade is paramount. Please consider this: the chef's knife sees the longest, most active, most continuous and regular use of any knife made for individual use. There are industrial knives that don't see as much use as the common kitchen knife. The person who is an established chef, whether as a hobby, interest, or vocation will use this type of knife daily, with little exception. Imagine any other sort of tool or instrument that is used daily. Wouldn't it be built to the highest standards that the user can afford? Would not the longevity of the knife be a significant, determinant factor in the knife design, style, and purchase? Could it be that short, limited life is built into factory and manufactured knives so that future sales can continue?

Blade Grind Longevity: In blades, the most important geometric attribute to the longevity of the fine chef's or kitchen knife is the grind. This is called a bevel in the common hobbyist terms, but make no mistake; it is a grind. Most manufactured and most handmade chef's knives are flat ground. This is necessary on only very thin blades, as detailed above. Flat grinding means that the cross sectional geometry dictates that as the knife is sharpened, it will become thicker. You can not ignore the fact that every knife must be sharpened over the course of its life, and, as stated earlier, this type of knife sees the most daily use. In order to be significantly thin after repeated sharpenings, a hollow grind is the best for knives over 1/16" thick, and a flat grind (taper grind) for knives less than 1/16" thick. You can clearly understand the reason for this as you look at the grind geometry profiles on my blades page and note the relief face widths and blade thicknesses after repeated sharpenings.

Why don't more makers and manufacturers use a hollow grind in their chef's and kitchen knives? Skill, time, and expense. It takes a very skilled and practiced hand to execute fine, balanced, matching hollow grinds on knife blades, and bringing those grinds to a high level of finish is beyond the skill of most makers (and all manufacturers). No matter how the grind is performed, a thin, long-time, thin serviceable edge is the goal. Sharpening is the only function that the knife owner or chef will perform himself, and to do so, a thin, functional grind is necessary.

Steel Type Longevity: Another important factor for knife blade endurance in the chef's knife is the steel type. Carbon steels are out as they rust and corrode, shortening the life of every chef's knife. Stainless steels like 420, AEB-L, 15N20, and 19C27 stainless are bad choices, even though 420 is the mainstay of nearly all chef's knives in the modern world! This is because 420 stainless, no matter how it's heat treated and processed, can only be 50-52 HRC in hardness. This is softer than a sewing needle, and softer than a wood cutting saw. It's so soft that, in order to be sharp, the steel must be continually sharpened, wearing away the steel at an extremely high rate. This "planned obsolescence" is great for the company that plans to sell you another knife set.

The best knives are built to last for generations. You won't live long enough to wear out a truly fine blade made with modern steel and methods, and will be handing the heirloom down to your grandchildren.

The finish longevity is a serious concern for the modern fine chef's knife. As detailed above, rough or coarse finishes are out, as they will hold moisture, grease, debris, foodstuffs, and bacteria. A fine finish will last a very long time, will resist corrosion, repel moisture, release foodstuffs, and facilitate easy cleaning. This will contribute greatly to the longevity of the knife blade. The very best finishes have always been and will continue to be mirror polishes. This is also the most difficult finish to achieve. Which is why you'll never see it on lesser knives.

The fittings of a fine chef's or kitchen knife consist of the bolsters, pins, ferrules, guards, pommels, and other fastening agents or mechanisms that mount and solidify the handles, strengthen the blade to handle junction, and protect the vulnerable parts of the knife and handle. They can also create or enhance grip areas, aid in corrosion prevention and create easy maintenance and cleaning. Some fittings allow areas for embellishment, personalization, and distinction.

The chef's knife handle can be an individual affair, and I'm often asked to make very distinctive and specifically designed handles. There is a reason for this. The distinctive and well-made knife handle is what often sets the individual knife apart from every other knife in the world.

Here are some emails that illustrate one of the typical and looming issues of poorly made knives. Sadly, these knives are touted as "The Best Chef's Knives" by the factories that sell them.

Jay, I have a Sabatier boning knife with a broken 3-rivet Micarta handle. Would you give me a

price for replacing the handle?

Thanks.

B. L.